Precise and reliable in wind and weather: PTB (Physikalisch Technische Bundesanstalt, the German national test authority) realises worldwide unique calibration baseline with MICROSENS switches

Measurements under under real conditions

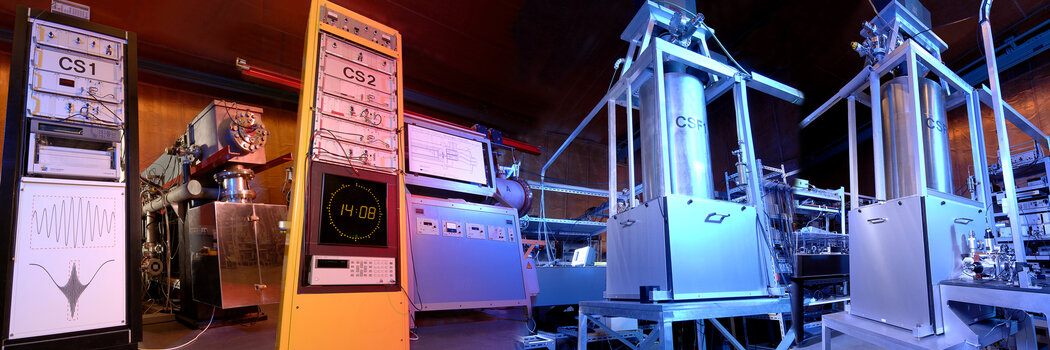

PTB is the epitome of precision and reliability. After all, the national metrology institute is responsible for measurement of official time in Germany. Several atomic clocks in Braunschweig ensure that we keep synchronised. However, measurement and research is conducted in quite a number of other areas, including geodetic metrology. In 2011 the institute extended a line of posts originating from the 1970s to produce a high-precision calibration station. Electro-optical distance measurement devices use laser beams to determine distances. But the propagation speed of light depends on very many external influences. If a measurement requires high accuracy, the temperature, humidity and air pressure have to be known precisely. For this reason, PTB installed 60 temperature sensors, six humidity sensors and two pressure sensors on the posts beside the centring stations along the line. Every 30 seconds these sensors have to measure the environmental data along the line. Although measurement alone is not enough, of course. The data have to be forwarded quickly and reliably to a central unit. For this purpose, the IT department at PTB, headed by Holger Seifert, received the task of constructing an effective network along the line. The requirements placed on the switching components sought were highly exacting:

- They had to withstand all outdoor temperature fluctuations, because, although the distribution cabinets are heated, they cannot be cooled.

- The components had to be constructed to be very compact and ideally they should be mountable on the DIN rail.

- They should have at least two optical outputs, so they are capable of realising the optical bus structure.

Gigabit switching in all weathers

In search of a suitable product, the decision was made for Gigabit Ethernet industrial switches from MICROSENS. Holger Seifert from the Data Networks working group explains: "We chose these industrial switches, as they are very robust and compact at the same time. They work without a hitch at temperatures between minus 40 and plus 70 degrees Celsius." A total of six switches were installed in distribution boxes placed very 100 metres along the measuring line. Each measurement distributor accommodates a temperature measuring instrument that collates the data from eleven sensors and a humidity meter with two sensors. Moreover, two measurement distributors are each equipped with a pressure measurement device. All measurement instruments are connected via patch cables to the switch and the switches are coupled together with fiber optics. The measurement data are combined directly on the line in an air-conditioned laboratory container in which the central unit is located. Since their installation in 2011, the switches have been working 365 days a year and have already withstood extreme weather conditions on many occasions. For Tobias Meyer, who provides technical support for the baseline, this is of crucial importance: "We regularly rent out the baseline to other authorities, surveying engineers and research institutions. They use the line fully autonomously and expect that all data are precisely recorded and transmitted without problems."

Successful collaboration

Under favourable weather conditions, the baseline in Braunschweig, with its worldwide unique construction, achieves an expanded measurement uncertainty of below 0.8 millimetres over a distance of 600 metres. This only succeeds if the average temperature along the entire measuring line under investigation is known to 0.15 Kelvin at all times. Here PTB cannot afford data loss or failures in information transfer. Holger Seifert emphasises: "We built our first optical final stage network with MICROSENS components in 1997. Since then, in numerous products we were able to be conviced of the reliability of the products. This experience has also been reaffirmed in the field of industrial switches."

About MICROSENS

Transmitting information via fiber optic connections offers numerous benefits. MICROSENS GmbH & Co. KG recognised this very early on. As one of the pioneers, the company has developed and produced high-performance communications and transmission systems in Germany since 1993. Individually matched to the demands of diverse usage areas and embedded in comprehensive concepts for individual sectors. But, above all, close to the customer. Technical challenges from customer projects are incorporated directly into product development. This way, IP-based automation solutions are created for modern buildings, cost-efficient network concepts for the office and workspace, robust and fail-safe solutions for industrial environments, optical transport systems future-oriented wide area networks and efficient coupling of sites and computer centres.